Dongguan City Jiexin Electromechanical Equipment CO., LTD.

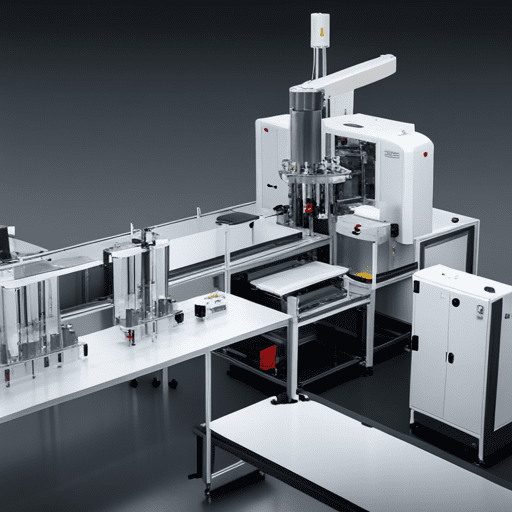

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

Industrial automation has revolutionized various industries, including connectors, automotive connectors, wire harness manufacturing, food and beverage processing, pharmaceuticals, electronics assembly, metal assembly, and plastic assembly. Let’s analyze the applications and advantages and disadvantages of industrial automation solutions in each of these industries.

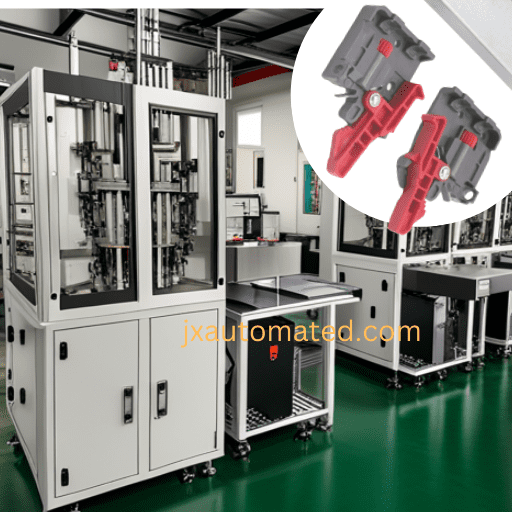

Automotive connector Manufacturing:

Applications: Industrial automation can be used in automotive manufacturing for Fakra connector & wire harness assembly line production, automotive connector assembly equipment, welding, painting, and quality control.

Advantages: Automation leads to higher productivity rates, better product quality, and increased safety for workers. It also leads to shorter workweeks for labor and reduced factory lead times.

Disadvantages: High capital expenditure required, higher level of maintenance, and lower degree of flexibility.

There are various types of automatic connector assembly equipment available to meet specific requirements for connector assemblies. Automatic assembly equipment offers numerous advantages, such as increased production speed, improved efficiency, and reduced labor costs. The use of automatic equipment can lead to faster assembly times and increased production volumes, which can improve the overall output of the assembly line. Furthermore, automated equipment can reduce the need for manual labor, which can help to reduce labor costs over time.

However, there are also some disadvantages to consider when choosing automatic connector assembly equipment. One of the main disadvantages is the high initial capital investment required to purchase and install the equipment. Additionally, a skilled workforce is needed to operate and maintain the equipment, which can add to ongoing labor costs.

Despite these disadvantages, a well-managed investment in automatic connector assembly equipment can provide a strong ROI with margins that improve over time as production increases and labor costs decrease. Assemblies such as Automotive Connectors, Board-to-Board Connectors, Card Edge Connectors, FFC / FPC Connectors, High-Speed Internal IO, I/O Connectors, Modular Jacks and Plugs, Sockets, Storage and Memory Connectors, and Wire-to-Board Connectors can all benefit from the use of automatic connector assembly equipment.

Applications: Industrial automation can be used in electronics, communication electronics, assembly for soldering, inspection, and testing.

Advantages: Automation leads to higher productivity rates, more efficient use of materials, better product quality, and increased safety for workers. It also reduces human error.

Disadvantages: High capital expenditure required, higher level of maintenance, and lower degree of flexibility.

how to purchase good automation equipment for manufacturing automotive wire harness, HSD cables, Fakra cable, data cables by considering various factors.

Firstly, you need to consider the specific requirements for each type of cable you are producing. This includes analyzing the type and volume of cables being produced, desired level of automation, and the budget.

Secondly, it is important to work with an experienced supplier who can provide customized solutions and ongoing support. Additionally, you should conduct thorough testing and analysis to ensure that the equipment meets your quality and performance standards.

Finally, achieving high levels of automation is crucial to maintaining competitive prices and production efficiency. By taking these factors into consideration, you can purchase automation equipment that will help manufacture high-quality automotive cables.

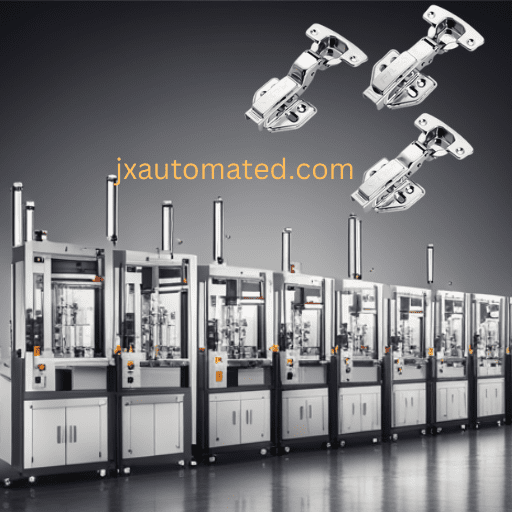

Disadvantages of automated assembly of terminal blocks:

High initial cost: The cost of purchasing and installing automated assembly equipment can be high.

Limited adaptability: The assembly equipment has a specific design for assembly, which can limit its ability to adapt to different terminal block types, thus decreasing the flexibility of the assembly process.

Technical expertise: Automated assembly requires experienced professionals to install, operate, and maintain the equipment.

In conclusion, automated assembly of terminal blocks offers several advantages over manual assembly, including increased speed, precision, and cost-effectiveness. However, it is important to carefully consider the initial cost, adaptability, and technical expertise required when deciding whether to invest in automated assembly equipment

There are several types of terminal blocks, which can be categorized based on their shape, size, and their electrical and mechanical properties. Some common types of terminal blocks include:

Barrier Terminal Blocks:

Pluggable Terminal Blocks:

Feed-Through Terminal Blocks:

Ground Terminal Blocks:

Fuse Terminal Blocks:

Advantages of automated assembly of terminal blocks:

Increased speed: Automated assembly is faster than manual assembly, which reduces production time and increases output.

Increased precision: Automated assembly ensures consistent and precise assembly of each terminal block, which enhances the overall quality of the product, reduces rework and repairs and reduces product failure rates.

Cost-effectiveness: Automated assembly reduces the need for labor, lowering labor costs, and ensures that the assembly equipment runs efficiently for a longer period, thus reducing maintenance expenses.

Applications: Industrial automation can be used in pharmaceuticals for filling and packaging, labeling, and quality control.

Advantages: Automation leads to higher productivity rates, more efficient use of materials, better product quality, and increased safety for workers. It also reduces human error.

Disadvantages: High capital expenditure required, higher level of maintenance, and lower degree of flexibility.

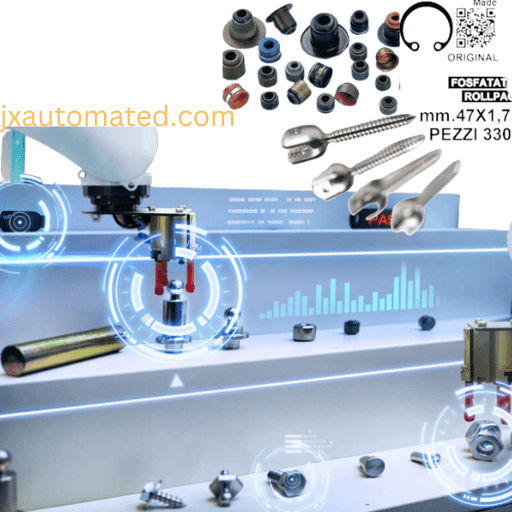

Application: Industrial automation is used for the Appearance inspection of

• valve seals, • Presence/Absence detection of part

• Defect detection

• Automated vision test & measurement

• Pattern matching

• Vision-guided robot

• Part verification (orientation, function, dimension, finished part features)

• Optical character recognition & verification (OCR/OCV)

• Color verification

• Sorting

• Barcode reading and traceability,

• medical screws,

• watch precision gears, etc. inspecting and sorting products based on their visual characteristics.

Advantages: Increased productivity, better product quality, and improved precision.

Disadvantages: High capital expenditure, limited to visual inspection only, and lower flexibility.

Applications: Ethernet transformers, Power transformers, Signal transformers, HCT transformers, Planar transformers, Chip LAN transformers, BMS transformers, Isolation transformers, Line Matching transformers etc…

Advantages: When analyzing different types of transformers for transformer assembly testing packaging automation machine lines, it is important to consider various factors like voltage level, kVA rating, size, maintenance, and testing. Evaluating the specific requirements of the assembly line is also crucial. Thorough testing and analysis of the transformers’ performance characteristics can help determine the best transformers for the job. It’s important to consider the cost of each transformer type, its maintenance requirements, and its expected lifespan. ROI depends on the initial investment cost, maintenance costs, and the expected lifespan of the transformer. The analysis can take several weeks depending on the complexity of the assembly line and the transformers involved.

Applications: Industrial automation can be used in metal assembly for welding, cutting, and shaping.

Advantages: Automation leads to higher productivity rates, more efficient use of materials, better product quality, and increased safety for workers. It also reduces human error.

Disadvantages: High capital expenditure required, higher level of maintenance, and lower degree of flexibility.

Applications: Industrial automation can be used in plastic assembly for injection molding, labeling, and quality control.

Advantages: Automation leads to higher productivity rates, more efficient use of materials, better product quality, and increased safety for workers. It also reduces human error.

Disadvantages: High capital expenditure required, higher level of maintenance, and lower degree of flexibility.

Overall, Factory automation offers many benefits to various industries, such as increased productivity, better product quality, and increased safety for workers. However, industrial automation also has some drawbacks, such as high capital expenditure and lower flexibility. Therefore, it is important to analyze the benefits and drawbacks of industrial automation solutions before implementing them in any industry.

Get notified about new articles