Dongguan City Jiexin Electromechanical Equipment CO., LTD.

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

Finding the right connectors and wire harness automatic assembly machine line depends on various factors including the specific needs of your production process. Consider the following:

– Determine the type and size of connectors and wire harnesses you need to produce.

– Assess the required production capacity and output rate.

– Look for machines with user-friendly interfaces, intuitive controls, and efficient automation features.

– Consider the compatibility of the machine line with your existing production setup.

– Evaluate the reputation and reliability of the manufacturers providing the machine line.

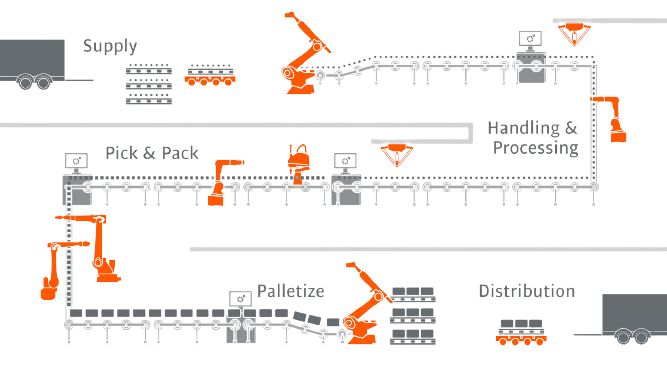

Using connectors and wire harness automatic assembly machines offers numerous advantages:

– Increased production efficiency and speed, leading to higher output rates.

– Enhanced product quality and consistency due to precise and accurate assembly.

– Reduction in manual labor requirements, resulting in cost savings and improved work safety.

– Seamless integration with other production processes.

– Improved adaptability to different connector and wire harness types.

– Minimized risk of human error, leading to reduced rework and waste.

Yes, connectors and wire harness automatic assembly machines are designed to handle various types and sizes of connectors. These machines can be customized and configured to accommodate specific connector dimensions, pin counts, and types such as solder lug, crimp, PCB, or IDC connectors. Ensure to communicate your requirements to the machine manufacturer to ensure compatibility with your desired connector specifications.

Connectors and wire harness automatic assembly machines are designed with user-friendly interfaces and intuitive controls to simplify operation. Manufacturers provide training and support to operators to ensure a smooth transition and efficient functioning of the machines. In addition, the machines are equipped with comprehensive manuals and online resources for assistance. With proper training and understanding, operators can easily handle and operate these machines.

Maintenance for connectors and wire harness automatic assembly machines involves regular cleaning, inspection, and lubrication to ensure optimal performance and longevity. Dongguan City Jiexin Electromechanical Equipment CO., LTD. provide maintenance guidelines and schedules along with recommended spare parts for replacements. It is recommended to follow these maintenance procedures diligently to minimize downtime and maximize the lifespan of the machines. Additionally, manufacturers often offer technical support and assistance for troubleshooting any issues that may arise.

Get notified about new articles