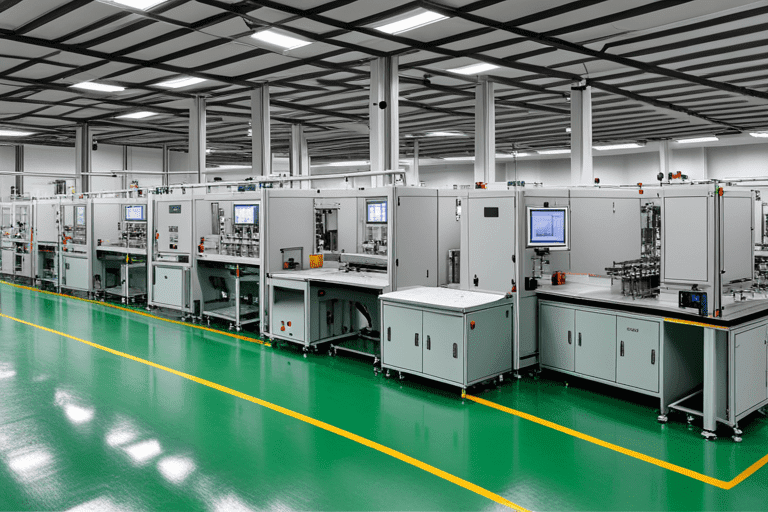

Dongguan City Jiexin Electromechanical Equipment CO., LTD.

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

15+yrs Professional High-speed connectors & Fakra Cable assemblies automated assembly line & solutions

Automated visual inspection (AVI) and manual visual inspection (MVI) are two methods used to inspect product appearance. AVI uses computer vision and image processing algorithms to detect defects in products, while MVI relies on human inspectors to visually examine products for defects.

AVI is often faster and more accurate than MVI, as it can detect defects that may be missed by human inspectors. AVI can also be programmed to inspect products consistently, ensuring that all products are inspected in the same way.

On the other hand, MVI can be more flexible, as human inspectors can adapt to different types of products and defects. MVI can also be more cost-effective for smaller production runs, as setting up an AVI system can be expensive.

Both AVI and MVI have their advantages and disadvantages, and choosing between them depends on the specific needs of the production process.

Get notified about new articles